Product Introduction

SWE-FP is a newly upgraded low-temperature homogenizer, which can reach a temperature as low as -50℃ in the chamber and also equipped with a freezing table. Adopt high-speed reciprocating motion of the vertical shaking system, the frozen sample in the grinding tube collides with the grinding bead, and the resulting grinding shear force and impact force completely break down the tissue. Up to 192 samples can be processed simultaneously in one minute, making it a dedicated device that meets the requirements of rapid processing of multi-sample.

Product Features

1. Slider drive, no wear shaft, noise stability and durability;

2. Equipped with low temperature freezing table. It can meet the needs of sample storage, electrophoresis, membrane transfer and other low-temperature experiments

3. Imported compressor, lowest cooling temperature of -50℃,low temperature grinding throughout the process, reducing degradation of proteins and RNA.

4. Up to 192 samples can be processed simultaneously in 1 minute (24 samples can be processed with standard),efficiently and effectively completing sample grinding with high throughput.

5. Multiple adapters to choose.

Technical Parameters

1. Dimensions: Length 650mm,Width 420mm,Height 430mm

2. Weight:54 kg

3. Screen size:5 inches

4. Temperature:-50℃

5. Temperature control precision:±1℃

6. Working time:Runtime0-9999s,pausetime0-999s,andruntimes1-99times

Parameters Comparison

|

Cat. No. |

KZ-III |

KZ-III-F/FP |

KZ-5F-3D |

SWE-FP |

|

Operating mode |

The vertical shaking system moves back and forth at high speed. |

the vertical shaking system moves back and forth at high speed |

Move in a "∞" shaped three-dimensional motion in space. |

The vertical shaking system moves back and forth at high speed. |

|

Temperature |

Room temperature |

-10℃/-40℃ |

-40℃ |

-50℃ |

|

Temperature control precision |

N/A |

±1℃ |

±1℃ |

±1℃ |

|

Standard spec. |

24*2 mL |

24*2 mL |

24*2 mL |

24*2 mL |

|

Maximum sample volume |

60 pcs |

60 pcs |

24 pcs |

192 pcs |

|

Adapter specification |

24x0.5mL. 24x2mL. 32x2mL. 48x2mL. 60x2mL. 12x5mL. 10x10mL. 6x5mL (steel can). 4x30mL (steel can). 2x50mL (steel can) and 8*15mL (steel can) |

24*2mL. |

24x0.5mL.24x2mL.48x2mL. |

|

|

Freezing table |

N/A |

N/A |

N/A |

YES |

|

Adapter fixing method |

Nut |

Nut |

Knob cover with safety locking device |

Nut |

|

Working time |

0-99min99s |

0-99min99s |

0-99min99s |

0-99min99s |

|

Dimensions |

365*265*396mm |

370*365*500mm |

650*420*430mm |

|

|

Screen size |

5 inches |

5 inches |

5 inches |

5 inches |

|

Emergency stop button |

YES |

YES |

YES |

YES |

|

Electromagnetic safety lock |

Screen click control with automatic power-off unlocking. the cover cannot be opened during operation until the grinding program ends, fully protected. |

|||

|

Maximum feeding size |

No requirements, adjustable according to the adapter. |

|||

|

Weight |

30.7kg |

45kg |

52kg |

54kg |

|

Power parameters |

200-240VAC,50-60 Hz, |

200-240VAC,50-60 Hz, |

200-240V AC,50-60 Hz, |

200-240VAC,50-60 Hz,500 W |

|

Cooling method |

Low temperature pre-cooling: adapter can reach -80℃ or liquid nitrogen pre-cooling |

Compressor cooling |

Compressor cooling |

Compressor cooling |

|

Transport screws |

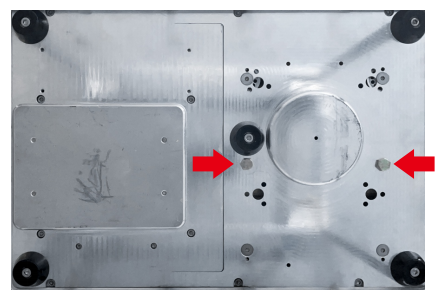

Yes (2 at the bottom) |

Yes (2 at the bottom) |

N/A |

Yes (2 at the bottom) |

|

Advantages |

Small size, cost-effective |

Compatible with various adapter specifications. |

Higher grinding efficiency, reducing tissue degradation. Freezing function, lowest temperature can reach -40℃. |

Lower cooling temperature can reach -50℃. low temperature freezing table, |

Unboxing and Installation

Remove the high-speed low-temperature tissue grinder from the packaging box and place it in a suitable location. Confirm that all components are complete.

Use the wrench provided in the accessories to remove the two fastening screws at the bottom of the instrument. (Before the first grinding operation, make sure to remove the fastening screws.)

Place the machine on a level and flat laboratory bench to prevent vibrations during operation.

Let it stand for 10 hours to ensure the coolant is in place. Connect the power supply (200-240V) and turn on the power switch at the back of the grinder.

Turn on the compressor cooling switch and wait for 10-15 minutes. Observe if the temperature in the grinding chamber reaches the set temperature.

6.If the temperature reaches the set temperature, install the adapter and nut correctly, then cover the top and start the machine.

Sample Preparation

The adapter can be used to grind 96 samples simultaneously in a 96-well plate. The adapter includes a base that can hold a 96-well plate, a top cover, and a locking nut.

Take the samples to be ground and place them in the grinding tubes. It is recommended to use no more than 100mg of sample. Add the corresponding extraction solution, ensuring that the total volume of the sample and extraction solution is within half of the overall volume. Add a few appropriately sized grinding beads. To ensure grinding efficiency and quality, for larger volume samples, it is recommended to cut them into smaller pieces using scissors.

Unscrew the locking nut and remove the top cover. Place the grinding tubes into the adapter, then attach the top cover and tighten the locking nut in a clockwise direction. (The placement of the tubes should follow the principles of symmetry and balance.)

Operation Steps

Plug the power cord of the grinder into a grounded 220V power outlet, and turn on the power switch at the back of the grinder.

After the startup interface is displayed, wait for about 5 seconds to enter the main operating interface.

Once the grinder is turned on, the cooling system starts running. Place the grinding tubes containing the samples, tighten the adapter, and cover the top of the grinder.

Set the operating frequency, time, and number of cycles. Click the "Temperature Selection" button to choose the temperature mode and set the desired temperature for the grinding chamber or the cooling platform.

Click the start button to begin the grinding process. The instrument will automatically stop once the timer reaches zero.

Equipment Maintenance

Perform the following routine maintenance after each use to ensure the reliable operation of the grinder.

Make sure to turn off the power and unplug the power cord before cleaning.

If solvents, salt water, acidic or alkaline solutions are spilled on the grinder, immediately wipe them clean with a damp cloth to avoid damaging the instrument.

Do not use high-pressure sterilization on any part of the grinder, including the adapter.

The components of the adapter should be cleaned after use. Use an appropriate cleaning agent, rinse with distilled water, and then wipe dry with a paper towel.

After using an appropriate cleaning agent, wipe the grinder clean with a soft cloth.

The following disinfectants and cleaning agents are recommended for cleaning the grinder and adapter:

a) Ordinary cleaning agent

b) Neutral detergent

c) 70% alcohol content

Equipment List

|

No. |

Product Name |

Model/Specification |

Quantity |

Remarks |

|

1 |

Tissue Homogenizer |

SWE-FP |

1 |

|

|

2 |

Standard Hollow Adapter |

2mL*24 |

1 |

Can process 24 samples at once |

|

3 |

Beads Pen |

SYM-04Z |

1 |

Suitable for 2mL grinding tubes, zirconia beads 4mm |

|

4 |

Beads Pen |

SYM-04B |

1 |

Suitable for 2mL grinding tubes, steel beads 4mm |

|

5 |

Beads Pen |

SYM-03B |

1 |

Suitable for 2mL grinding tubes, steel beads 3mm |

|

6 |

2mL Centrifuge Tube |

1 |

Tube wall is thickened, material strength is higher, and there is no RNA enzyme. |

Protein Extraction

|

Product Name |

Grinding Beads |

Frequency |

Grinding Time |

Pause Time |

Cycle times |

Recommended Extraction Solution |

|

Plant Stems, Leaves |

Stainless Steel Beads 3mm*3, 4mm*1 |

60Hz |

60s |

15s |

3 |

Protein Extraction Solution |

|

Heart, Liver, Spleen, Lungs, Kidneys, Brain of Mice and Rats |

Stainless Steel Beads 3mm*2, 4mm*1 |

60Hz |

30s |

15s |

2 |

Protein Extraction Solution |

|

Stomach, Intestines, Muscles, Fat, Pancreas of Mice and Rats |

Stainless Steel Beads 3mm*2, 4mm*1 |

60Hz |

45s |

15s |

2 |

Protein Extraction Solution |

|

Skin, Ears, Tail, Blood Vessels of Mice and Rats |

Stainless Steel Beads 3mm*3, 4mm*2 |

70Hz |

60s |

20s |

3 |

Protein Extraction Solution |

|

Cartilage, Hair, Hard Bones of Mice and Rats |

Stainless Steel Beads 3mm*4, 4mm*2 |

70Hz |

90s |

20s |

3 |

Protein Extraction Solution |

(This condition is for reference only, and can be adjusted at any time during the experiment according to the grinding effect.)

RNA Extraction

|

Product Name |

Grinding Beads |

Frequency |

Grinding Time |

Pause Time |

Cycle times |

Recommended Extraction Solution |

|

Plant Stems, Leaves |

Zirconia Beads 3mm*3, 4mm*1 |

60Hz |

60s |

15s |

3 |

RNA Extraction Solution |

|

Heart, Liver, Spleen, Lungs, Kidneys, Brain of Mice and Rats |

Zirconia Beads Beads 3mm*2, 4mm*1 |

60Hz |

30s |

15s |

2 |

RNA Extraction Solution |

|

Stomach, Intestines, Muscles, Fat, Pancreas of Mice and Rats |

Zirconia Beads Beads 3mm*3, 4mm*2 |

60Hz |

45s |

15s |

2 |

RNA Extraction Solution |

|

Skin, Ears, Tail, Blood Vessels of Mice and Rats |

Zirconia Beads Beads 3mm*4, 4mm*2 |

70Hz |

60s |

20s |

3 |

RNA Extraction Solution |

|

Cartilage, Hair, Hard Bones of Mice and Rats |

Zirconia Beads Beads 3mm*3, 4mm*4 |

70Hz |

90s |

20s |

3 |

RNA Extraction Solution |

(This condition is for reference only, and can be adjusted at any time during the experiment according to the grinding effect.)

For RNA extraction, the grinding time is extended compared with that of protein extraction, and RNA extraction solution is added to the grinding, the specific grinding time depends on the amount and type of tissue to be ground. Samples difficult to break can be repeated grinding 2-3 times, the specific situation can be adjusted appropriately according to the experiment.

Strong and Tough Tissue Grinding

For samples that are difficult to grind (e.g. cartilage, hair, etc.), we recommend using a 2mL grinding tube. Cut the sample into 1-2mm pieces, add the appropriate number of grinding beads, cover the tube tightly and freeze in liquid nitrogen for 2-3min without extracting solution, dry grind for 60 seconds at 70Hz, then add extracting solution to the tube and repeat the grinding once. If the grinding result is not satisfactory, the tube can be frozen again and the above experimental steps can be repeated.

Bone Tissue Grinding

For bone tissue, use the special steel grinding jar and adapter. The bone tissue is first frozen in liquid nitrogen for 5-10min, then put into the grinding jar, add the steel beads, and grind for 180 seconds at 70Hz (set cycle grinding). After grinding, take out the finished tissue, put it into a 2mL grinding tube, add the extraction solution, two 3mm grinding beads and homogenize for 60 seconds.

|

Cat. No.

|

Product Name

|

Spec.

|

|

|---|

|

KZ-5F-3D

|

3D Tissue Homogenizer (-40℃)

|

(-40℃)

|

|

KZ-III

|

Tissue Homogenizer (Room Temperature)

|

Room Temperature

|

|

KZ-III-96

|

Tissue Homogenizer Room Temperature (96-well Plate)

|

Tissue Homogenizer Room Temperature (96-well Plate)

|

|

KZ-III-F

|

Tissue Homogenizer Low-temperature (-10℃)

|

(-10℃)

|

|

KZ-III-FP

|

Tissue Homogenizer Low-temperature (-40℃)

|

(-40℃)

|

|

KZ-III-YLS

|

Water-quality Chlorophyll Homogenizer

|

Room Temperature

|

|

SWE-FP

|

Tissue Homogenizer Low Temperature (-50℃, Freezing Table)

|

(-50℃, Freezing Table)

|

You may also like

-

SERVICEBIO Tissue Homogenizer (Room Temperature) 24 samples

![]()

- Regular price

- €3.298,95 EUR

- Sale price

- €3.298,95 EUR

- Regular price

-

- Unit price

- per

Sold out -

SERVICEBIO Tissue Homogenizer (Room Temperature)

![]()

- Regular price

- €4.140,95 EUR

- Sale price

- €4.140,95 EUR

- Regular price

-

- Unit price

- per

Sold out -

Recombinant Salmonella typhimurium Bifunctional protein aas(aas)

![]()

- Regular price

- €1.469,95 EUR

- Sale price

- €1.469,95 EUR

- Regular price

-

- Unit price

- per

Sold out -

Recombinant Rhodothermus marinus ATP-dependent zinc metalloprotease FtsH(ftsH)

![]()

- Regular price

- €1.453,95 EUR

- Sale price

- €1.453,95 EUR

- Regular price

-

- Unit price

- per

Sold out